- Call for Service! +91 (0)11 43565446

- Email : safety-india@sigma-hse.com

Standard

Prevention of Fires and Explosions in Dryers – John Abbott

AIR OVER LAYER TEST

The air over layer test is conducted to establish the onset temperature of exothermic activity of thin layers of material when exposed to elevated atmospheric temperatures. It replicates thin layer (up to 15 mm) deposits in any drying situation i.e. drier walls and roof where hot air rushes over its surface.

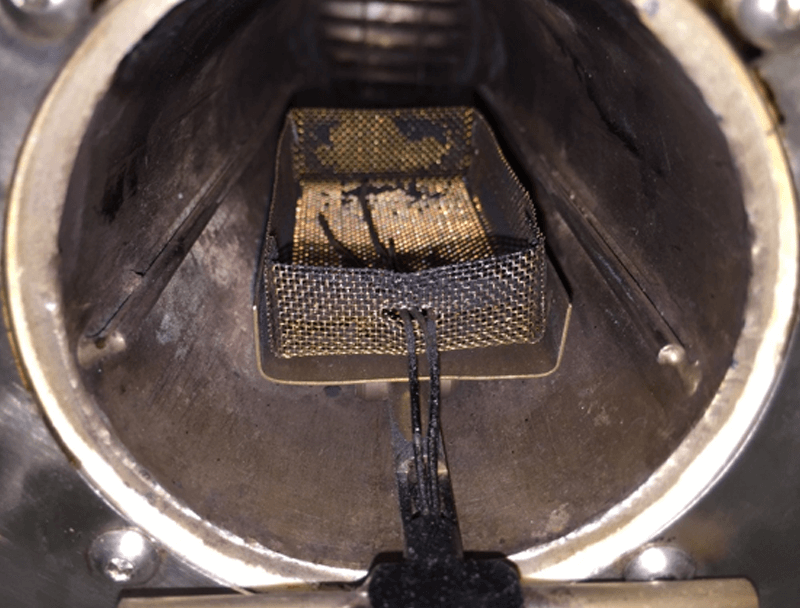

Using a small tray test cell, the sample is placed inside the cell and thermocouples placed into the material at three locations. This assembly is placed into a digitally controlled, horizontal, laboratory tube oven with controlled heated air supply and either of the following tests performed using a data acquisition system to monitor, detect and record any exothermic activity.

SCREENING TEST

The environmental temperature is digitally ramped from ambient conditions up to 400°C at 0.5°C.min-1. This test configuration is used for estimating exothermic activity onset temperature.

ISOTHERMAL TEST

The loaded test cell is placed into a heated oven, set to a specified temperature for a duration of 24hr. The temperature selected can either be based on working or proposed process conditions (plus a factor of safety) or full determination can be undertaken, conducting several isothermal tests to establish a definitive ignition temperature.

Benefits

Not only is the air over layer test a necessity in evaluating whether current or proposed drying and process temperatures are safe, it can also confirm the possibility of using a higher temperatures to increase productivity.